In water quality testing, the gravimetric method is one of the commonly used methods, especially when detecting the oil content in water. The advantage of this method is that it is not limited by the type of oil, and is suitable for the determination of water samples with an oil content of more than 10 mg/L.

The principle is to add the coagulant aluminum sulfate to the water sample, so that the oil particles dispersed in the water will be agglomerated by the initially formed aluminum hydroxide. With the precipitation of aluminum hydroxide, a small amount of oil in the water can be gathered in the sediment. After acidification, the precipitate can be dissolved again, and the separated oil can be transferred to the organic solvent through organic solvent extraction. Then the organic solvent is evaporated to dryness, and the residue is oil in water. The oil content in water can be obtained by weighing. Let’s take a look at the detailed steps of the gravimetric method for detecting oil in water today.

1. 5~10L sampling bottle with ground stopper.

2. Separating funnel 500mL.

3. 100mL porcelain evaporating dish.

4. Oven.

5. Analyze the balance.

6. Constant temperature water bath.

7. Dryer.

8. Aluminum sulfate solution

Weigh 30g of aluminum sulfate, dissolve in a small amount of distilled water and dilute to 100mL.

9. 20% anhydrous sodium carbonate solution.

10. Concentrated sulfuric acid.

11. Carbon tetrachloride.

1. Increase the flow rate of the tested water sample and take 5-10L of water sample. Immediately add 5-10mL aluminum sulfate solution (calculated by adding 1mL per liter of water sample), shake well, and add 5-10mL sodium carbonate solution (also calculated by adding 1mL per liter of water sample). Shake well to agglomerate the oil particles dispersed in the water in the sediment. Let it stand for more than 2 hours to allow the precipitate to sink to the bottom of the bottle, and then use a siphon to carefully suck off the supernatant liquid. Add a few drops of concentrated sulfuric acid to the remaining precipitate to dissolve the precipitate, and transfer the acidified solution into a 500 mL separatory funnel.

2. Take 100mL of carbon tetrachloride and pour it into the sampling bottle, and fully clean the oil stains on the wall of the sampling bottle. Transfer this carbon tetrachloride to the separatory funnel.

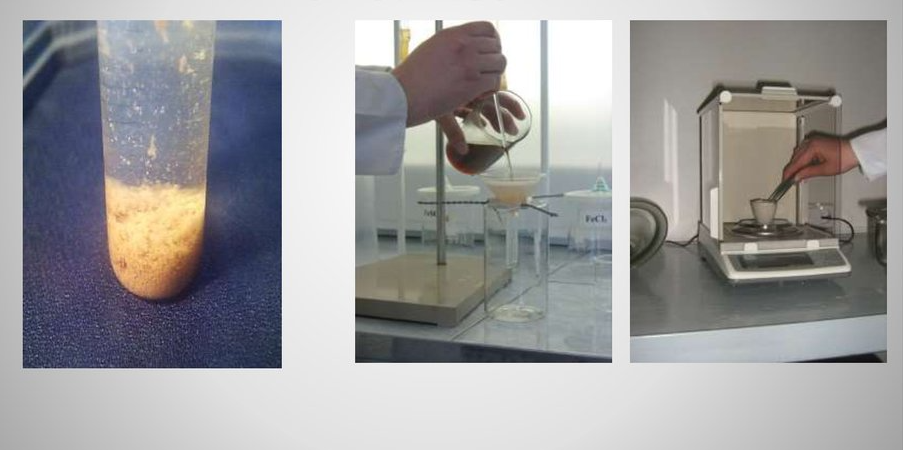

3. Shake well and extract the oil contained in the acidified solution, leave it to stand, after the layering is completed, filter the bottom carbon tetrachloride layer with a dry ashless filter paper, and filter the filtered carbon tetrachloride solvent Move into 100mL evaporating dish with constant weight, then rinse the separatory funnel and filter paper with 10mL carbon tetrachloride, and add the cleaning solution to the evaporating dish with constant weight.

4. Put the evaporating dish on the water bath, evaporate the carbon tetrachloride to dryness in a fume hood, then put the evaporating dish in an oven at (110±5)℃ for 2h, and place it in a desiccator to cool to room temperature , Weigh quickly. Repeat drying for another 30min, cooling, weighing, and repeat the operation until constant weight. Take another 100mL carbon tetrachloride in another constant weight evaporating dish for blank test.

1. It is recommended to add the extractant used in the method immediately after sampling, or perform on-site extraction.

2. To save the water sample, add 5mL sulfuric acid solution (1+1) per liter of the water sample to be stored to make the pH of the water sample <2 to inhibit microbial activity, and store at low temperature (<4℃)

3. When siphoning, the rubber tube should be moved carefully, so that most of the clarified water can be sucked away, but the sediment will not be taken away, otherwise the result will be low.

4. When putting carbon tetrachloride extractant from the separatory funnel, in order to prevent the aqueous solution (acid and salt solution) from entering the filtrate, it is better to leave a drop of carbon tetrachloride in the separatory funnel.

5. Carbon tetrachloride vapor is harmful to the human body. Avoid inhalation during operation. Evaporative drying must be carried out in a fume hood.

6. The extractant used in the same determination should be the same batch number. If multiple batches of extractant must be used, they should be mixed and used.

7. If the water sample is mixed with more particulate impurities, after extraction with carbon tetrachloride, there will be no obvious liquid separation layer at the water layer and the organic solvent layer. But this mixed layer can still be filtered with dry filter paper, because the dry filter paper will quickly absorb the water droplets in the mixed layer, and the carbon tetrachloride will pass through the filter paper, so it has no effect on the test results.

8. The piston of the separatory funnel cannot be coated with earth forest.

9. In order to save organic solvents, carbon tetrachloride can be recycled by distillation.

最新动态

相关推荐